V- belt pulley of different types . The material used is usually cast iron , and for just a few types it is metal. They have a small prebore which can be machined according to consumers’ requirements. Moreover the most typical types are available likewise with taperlock bore.

PRECISON CASTING Shed WAX CASTING STAINLESS HAND POLISHED PULLEY

Industrial parts, Machinery parts, construction parts, valve parts, pump parts, impeller parts, train ,craft, hydraulic pressure, Agricultural machinery, Marine hardware, Auto parts, energy fittings, food machinery, harness fittings, machinery parts

CAST IRON TIMING BELT PULLEY (3M, 5M, 8M, 14M, XL, H, L)

Our main items include: European pulley, American pulley, Couplings, taper bushing, QD bush, lock element, adjustable motor base, motor rail, sprockets, chain, bolt on hubs, weld on hubs, jaw crusher devices & spare parts and all types of non-standard Casting products etc.

OEM Grey Iron Sand Casting Tractor Parts Belt Pulleys

We hereby introduce our company as a leading producer of Machinery parts in china, we mainly doing casting parts, machining parts, plastic material injection parts, stamping parts and forging parts. various products rely upon our large factory who experienced over twenty years history and knowledge. and we are most proficient at OEM and CNC regarding buyer drawing or design.

Ever-power specialist in making all types of mechanical transmitting and hydraulic transmission like

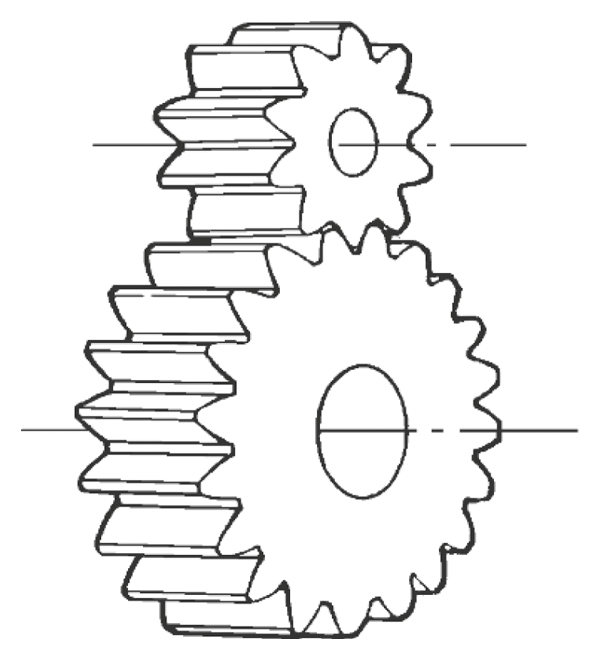

planetary gearboxes, worm reducers, in-line helical gear acceleration reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm gear reducers, agricultural gearboxes, tractor gearboxes, car gearboxes, pto travel shafts, special reducer

More Product

related gear components and additional related products, sprockets, hydraulic system, vaccum pumps, fluid coupling, gear racks, chains, timing pulleys, udl speed variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors shaft collars low backlash worm reducers and so forth. furthermore, we are able to produce customized variators, geared motors, electrical motors and different hydraulic goods according to customers’ drawings.

Accurate belt installation can be quite important when it comes to getting maximum life and efficiency from your belts. Take time to be certain that your belt pulleys happen to be properly prearranged with a straight edge and that they are not worn and cutting in to the belts. Proper belt stress should be placed with a belt tension tool that may also be purchased online and reset again after the first about a week of operation to permit for belts that extend, and all belts will stretch. Most of the stretching takes place in first hours of operation so it is vital to re verify vbelt tension following the belt has had some run time.

This technique operates to either reduce or increase speed or torque, and for power transmission between shafts, especially those that aren’t axially aligned. These two complement each other wherein the belt balances the strain while the pulley settings the speed. Understanding how they work will help you take advantage of their roles in boosting motor performance, and at the same time, help you choose ones that are also cost-efficient.

Right right now, there are a great number of belts available in the market that you may easily obtain. It would be a great help know the elements that will help you decide what sort of belt to use. A number of the features that you have to look for in belts are their high level of proficiency and, simultaneously, low level of maintenance. One more thing to consider is the optimum load and the original pressure of the belt. You will find a limit to the strain size before the belt slips and the original tension plays a huge role in deciding this factor. Too little initial tension can lead to a dead electric battery and the alternator belt slipping. Alternatively, too much initial tension will lead to deterioration of the belts and bearings.

Among the most well-liked belt drivers will be the V-belts. Their wedge action can produce a lot of friction and boost the power transmission ability. They have an estimated 5% reduction and 93% efficiency. On the other hand, if you are looking for a belt system to work very best with a vehicle, then you need the synchronous belt. It is also known as timing belt pulley which can control the opening and closing of engine valves. While you are looking for toothed-belts that require little repair and re-tensioning, then the belt pulley is usually your best choice. In addition, they are the most efficient, can function slip-free, and can do the job both in wet and oily surroundings.

With regards to v-belts their’s more to simply throwing them on and walking apart. Unfortunately in most cases that is exactly what’s done. Another misconception is definitely that v-belts do not need to be changed until they have completely broken and will not function at all. V-belts will stretch and begin slipping long before they will break. V-belt dressing will purchase you some short term time but isn’t the answer. An excellent preventive maintenance program may include instantly replacing vbelts every half a year according to equipment run time.

silica sol purchase casting,Sodium Silicate sand casting,Sodium Silicate expenditure casting, lost-wax expense casting, clay sand casting, furan resin sand casting, shell Casting, die casting

Taper bush pulley and stable hub pulley, various quickness pulley, smooth belts pulley, adjustable quickness v belt pulley, material is gray cast durability, they have good hardness and iron.

For American common pulley, they are suited to 3L,4L,5L,A,B,C,3V,5V,8V belt, after specific machining and ability painting ,they will get smoonth and beautiful surface area ,and good anticorrosive capacity

Huge Gray Iron Casting Belt Wheel Pulley can be produced by casting. Common used material can be GG25 or other custom-made material.

Strictly top quality inspection system can produce top quality products. Our quality qualification system is ISO 9001:2015. For each order,we provides report for material chemical substance components testing,UT tests,hardness, mechanical property testing(impact testing,yield power testing,tensile strength tests),size inspection,etc.

Metal Parts Choice for Vehicle, Agriculture equipment, Construction Machine, transportation tools, Valve and Pump program, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear field , gear housing , gear go over, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve casing ,Fitting , flange, wheel, fly wheel, essential oil pump housing, starter housing, coolant pump housing, transmitting shaft , transmission gear, sprocket, chains etc.

V- belts pulleys change from timing belt pulleys for the sort of belt ( V-section) they can fit in. HZPT possesses in stock an array of V- belt pulley of different types ( regarding to type and width of belts). The materials used is cast iron EN-GJL-250 UNI EN 1561, and for only a few types it is steel C45 E UNI EN 10083-1. They possess a small prebore which can be machined according to customers’ requirements. Moreover the most frequent types are available likewise with taperlock bore.

Catalog of V Taper Lock pulleys(European Standard Taper bore)SPA, SPB, SPC, SPZCatalog of Flat Belt Pulleys for Taper Bushes (European Normal)Catalog of Adjustable V Taper Pulleys(Euroepan Normal)Catalog of sheavesSheaves for 3L, 4L, A, 5L and B beltsAK, AKH, 2AK, 2AKH, BK, BKH, 2BK, 2BKH, 3BK, 3BKH

Metal Parts Answer for Vehicle, Agriculture machine,, transportation gear, Valve and Pump program, Agriculture machine steel Parts, engine bracket, vehicle chassis bracket, gear container , gear housing , valve go over, etc.

Film belts tend to be classified as a number of smooth belt, but actually they are a independent type. They contain an extremely thin belt (0.5-15 millimeters or 100-4000 microns) strip of plastic material and occasionally rubber. They are usually intended for low-ability (10 hp or 7 kW), high-speed uses, allowing high productivity (up to 98%) and long life. These are seen in business equipment, tape recorders, and various other light-duty operations.They are length adjustable by disassembling and removing links when needed.

WORM GEAR

Producer supplier exporter of worm gear

We warmly welcome consumers each in your house and abroad to speak to us to negotiate small business, exchange data and cooperate with us.

We specializing during the manufacturing of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and more.

Include things like one 0.5 modulus brass worm gear shaft and 1 20 teeth brass worm gear wheel.

The transmission construction of worm shaft is easy, compact, little volume and light excess weight.

Worm Shaft Z1=1, turn a round of worm gear teeth, could get a substantial transmission ratio, generally inside the electrical power

CAST IRON WORM GEAR REDUCER

The transmission is stable, the vibration, effect and noise are tiny, the reduction ratio is big, the versatility is broad, and it could be used with many mechanical equipment.

It could possibly get a considerable transmission ratio with single-stage transmission, and features a compact construction. Most designs have improved self-locking effectiveness, and can conserve braking gadgets for mechanical tools with braking demands.

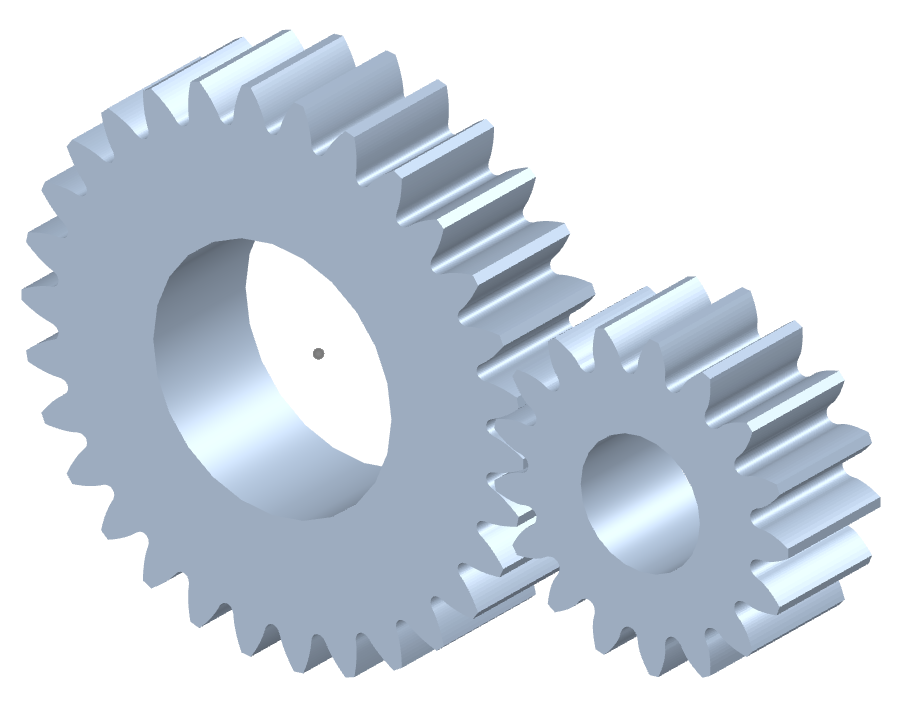

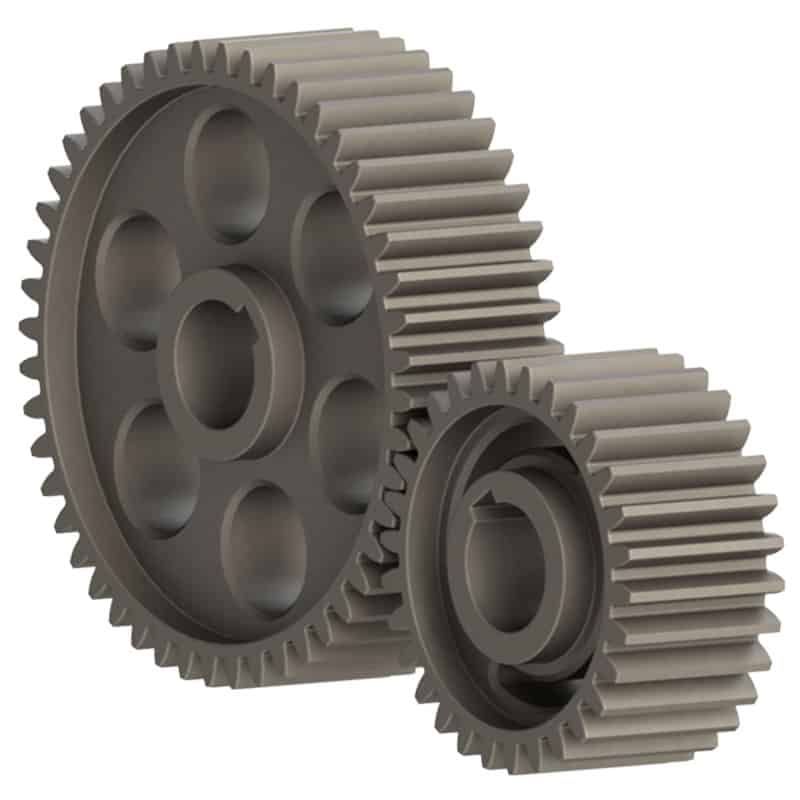

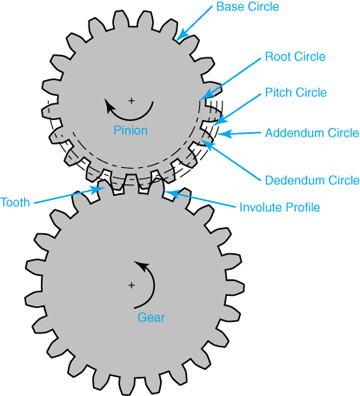

Gears helps us as a result of a mechanism of rotation concerning two axes to produce electrical power. So they, with the aid of rotation following a mechanical concept related to physics transfers velocity into energy. They may be of two sizes, 1 tiny and the other massive, adjoining one another with all the enable of teeth. The teeth are interlocked and trigger rotation.

WORM GEAR AND Strengths OF WORM GEARS

If between two gears one particular is heavier and also the other lighter it’s mentioned that the bodyweight gets to be the fantastic element to induce friction. If the bodyweight appears as well hefty rotation may very well be hampered leading to inconvenience to move the machine with which they may be attached.

Distinct gears have diverse teeth. The teeth are within a twisted type or in a straight form. It is the action of a helical 1 to radiate movement concerning two shafts. Whereas the bevel kind has teeth based upon conical surface. The shafts are hardly ever parallel and intersected sharply in an angle.

WORM GEAR Velocity REDUCER Business Speed REDUCER FOR Electric MOTOR

Two or three reducers may be used to kind a multi-stage reducer to acquire a terrific gear ratio.

A worm, in industrial parlance, is a shaft having a helical thread. It truly is commonly a component of the gear that meshes using a toothed wheel. Worm gears on the other hand, are these regarded as worm wheels. Sometime lots of folks are puzzled together with the terms worm, worm gear and worm drive, considering that these 3 imply precisely the same thing.

Worm gears are critical especially when there’s a require to cut back the gear size. It’s the worm that has the capability to generate the gear rotate and never another way about. Using the shallow angle about the worm, the gear isn’t going to possess the capacity to rotate it.

Types of worm gear

You will discover in essence three diverse varieties of worm wheels: the non-throated; single throated; and double throated. Non-throated worm wheels are those that don’t have throats in each the worms as well as the gear. Single throated categories are these whose gears are throated. Lastly, double throated ones are these with throated worms and gears.

Worm gear characteristics

You will find notable traits of a worm wheel. Initially, it has the capacity to transfer and carry load with utmost accuracy. It’s also greatest for huge speed reductions. The efficiency with the worm gear, nevertheless, depends on set up situations, the worm’s lead angle, sliding speed, surface good quality and lubricant choice.

Creating worm gears turn into productive

A method identified as double enveloping makes worm gearing turn out to be additional productive. This technology enhances the current features on the worm wheel. This leads to far better accuracy and enhanced torque. What tends to make the approach so unique would be the proven fact that it may be applied to provide better lubrication and style and design while loads are divided in each and every on the gear’s teeth.

Worm gear applications

Worm wheels make conveyor programs do its perform. Conveyors are tools to transfer a single material from one particular location to a different. Besides conveyor systems although, the worm wheel may also be utilized in large functionality cars.

Carbon Steel And Stainless Steel Conveyor Chain Hollow Pin Chain

Transmission chain(Driving Chain), Conveyor Chain ¡§C roller chain, Engineering Chain, Stainless Steel Chain, Lifting Chain, Agricultural Chain, Forging Series, Cast Iron Chain.

Hollow Pin Chains 08BP 40HP, 50HPSS, 60HP, 12BHP, 80HP, C2040HP, C2050HP, C2060HP, C2080HP, HB50.eight, C2042HP, C2052HP, C2062HP, C2082HP, C2042H-HP, C2052H-HP, C2062H-HP, C2082H-HP

Stainless Steel Roller Chain Stainless Steel Conveyor Chain

Stainless Steel Roller Chains,Stainless Steel Conveyor chain, Stainless steel chain for bottle conveyor line which is utilized on bottle filling conveyor lines, other normal ss chain or specific ss chains (SS304 chain, SS316 chains, SS316L chains, SS conveyor chains, SS304 conveyor chain, SS316 conveyor chain) all offered

Rust 304 Stainless Steel Chain/Lifting Chain

Rigging Hardware, Over 1000’s Selection. Including Connecting Website link, Safety Hook, Eye Hook, Clevis Hook, Master Hyperlink, Master Website link Assembly, And so on.

Series Zinc plated Agricultural Transmission Chain for Feeder residence Clear Grain

Attachment: K1, K5, K19, K30, K39, 220B, F4, F5, F14, F45, G18, TM91E, TM92, C6E, C11E, C13E, C30E, CPE, LV41N,

Surface Treatment method: Shot-Peening, Zinc plated.

Application: broadly employed in Feeder property, Clear Grain, Return Grain in agricultural machine.

CC600 Corrosion Resisting Cast iron Chain

Our CC 600 Conveyor chains are manufactured in malleable iron with steel pins, with pins that are unhardened. This verified style and design results in an assembled chain that is certainly really sturdy and wear resistant. Created withing the fuel bottling market (Especially Liquid Petroleum Gasoline ) our CC600 series stays a merchandise of to start with decision for distributors and finish end users alike, wherever a quality solution is required to start with time, just about every time. The CC600 chains are intended for use in multistrand conveyors dealing with person loads underneath conditions of mild corrosion. They can be commonly supported in channels and are extremely flexible, enabling for fluid motion and versatility when essential. This versatility lets them to become utilised within a assortment of hefty duty applications but their principal application is from the bottling sector the place they may be termed on to manage crates and gas bottles.

specializes in generating all types of mechanical transmission solutions and hydraulic transmission merchandise, this kind of as planetary gearboxes

Chains are series of linked links or rings that happen to be commonly produced of metal and may be linked or fitted into one another. Every piece of your chain can have greater than one particular hyperlink dependent on its application. Some employs of chains is often for fastening, binding or supporting objects. The 2 most typical variations of building chains are roller chains and those that are torus shaped. The kind of the chain depends on the application from the chain. Torus shaped chains are very frequent in lots of applications. They will be utilized for hoisting, securing or supporting and have a really very simple shape of rings that are connected to each other. This simple design and style provides these chains flexibility in two dimensions. Their simple style and design and versatility make it possible for them to be applied for a lot of duties such as securing a bicycle

Roller chains are incredibly widespread in bicycles. They are really built to transfer electrical power in machines. Taking bicycle chains one example is, they’re built to mesh using the teeth of the sprockets of the machine. Versatility in these chains is also limited because they can only move in one path. Some common applications of chains is usually as critical chains, snow chains and bicycle chains.

As stated earlier within this article, bicycle chains are roller chains. They transfer energy from pedals on the drive-wheel that in flip propels the bicycle forward. These chains are generally manufactured from plain carbon or an alloy of steel even so some is often nickel-plated to be able to prevent rust. These chains may also be thought of to be very power efficient. Although a lot of men and women may well assume the efficiency to be tremendously impacted through the lubricant, a review that was carried out inside a clean laboratory uncovered that instead of lubricants, a larger sprocket would present a additional effective drive. Also, the higher the tension within the chain, the much more efficient it would be.

single row 4 stage speak to ball slewing rings is composed of two seat rings, which style in compact structure and light bodyweight, steel ball speak to using the circular raceway at four factors; it can bear the axial force, radial force plus the tilting second in the exact same time. Coresun drive Single-row four stage contact ball ring has the attributes of compact in style, and light in bodyweight. The balls roll around the circular race at four factors, so it could undertake the axial force, radial force and tipping second at the very same time. This series of four level get hold of ball bearings are appropriate in many engineering machinery, for example rotary conveyor welding operation machine, tiny cranes, little and medium-sized excavators,slewing conveyer, welding manipulator, light and medium duty crane, and also other development machinery.

Three kinds of this kind of single row four level get hold of ball slewing bearing:

A. Without gear bearing (non tooth)

B. External gear bearing (external tooth)

C. Inner gear bearing (internal tooth)

double row diverse diameter ball slewing bearing is mainly produced up of in-up ring, in-down ring and outdoors ring, so balls and spacers could be straight discharged into the upper and reduced raceway. In accordance with worry ailments, bearings are organized to two rows of balls of various diameter. This assembly is incredibly convenient. Angle of each upper and reduce raceway is 90??so bearings can bear significant axial force and resultant torque. Bearing requires special design and style when radial force is 0.1 instances larger compared to the axial force. Substantial in sizes and attributes compact in style, bearings are particularly application in managing equipments requiring medium over diameter, for example tower crane and mobile crane.

single row cross roller slewing ring is mostly created up of inside and outside rings. It functions compact in design, light in bodyweight, little in assembling clearance, and large in putting in precision. Since the rollers are crossed organized by 1:one, it is ideal for substantial precision mounting and capable to bear axial force, radial force and resultant torque concurrently. This series single row crossed roller slewing bearing have broadly application in lift transport aircraft, development machinery, and military items.

one. Professional gears producer

two.Knowledgeable in Cooperate with large Corporations

3. Skilled gears Engineering Capability

four.Stable gears Good quality

5.Sensible gears Charges

six.Smaller gears Orders Accepted

seven.Constant gears high-quality improvements

eight. High gears high quality Overall performance

9.Brief gears lead time and shipment

ten.Qualified gears service

We can generate 6 patterns of slewing bearings in a assortment of specs with diameters ranging from 400 mm to 5050 mm. Our products show each day to be significant structural and connection aspects utilized in wind turbines, excavators, mobile cranes, harbor and shipyard cranes, robots, health care scanners and in general mechanical engineering.

Excellent Handle:

Excellent may be the essential to our good results. We’re committed to obtaining customers’ satisfaction by giving top quality services and products.

We be sure that our complete excellent management procedure is in accordance with ISO9001 regular and it is carried out successfully.

In pursuit of high-quality raw components, we undergo a stringent verification and selection course of action to select the best suppliers of forged rings along with other elements in China. If demanded, we are able to also apply more large-diameter forged rings developed by ThyssenKrupp in Germany.

Cranes are uniquely constructed, which suggests the slewing ring bearing is an necessary component of its style and design. High quality and precision during the manufacturing approach.

Gear transmission refers to the gadget that transmits motion and power from your gear pair. It’s the most widely utilised mechanical transmission technique in modern day products. Its transmission is additional correct, higher efficiency, compact structure, trustworthy operation and extended support existence.Our gears can be heat treated, hardened, oil immersed based on consumer wants.The gear is broadly utilized in industry, automobile, electrical power equipment, motor, bicycle, electrombile.

single row 4 level get hold of ball slewing rings is composed of two seat rings, which style and design in compact structure and light bodyweight, steel ball speak to together with the circular raceway at four factors; it might bear the axial force, radial force as well as tilting moment on the similar time. Coresun drive Single-row 4 level get in touch with ball ring has the functions of compact in design and style, and light in excess weight. The balls roll about the circular race at four points, so it could undertake the axial force, radial force and tipping minute at the same time. This series of four stage make contact with ball bearings are suitable in lots of engineering machinery, such as rotary conveyor welding operation machine, compact cranes, modest and medium-sized excavators,slewing conveyer, welding manipulator, light and medium duty crane, as well as other building machinery.

3 kinds of this sort of single row 4 level get in touch with ball slewing bearing:

A. With no gear bearing (non tooth)

B. External gear bearing (external tooth)

C. Internal gear bearing (internal tooth)

double row diverse diameter ball slewing bearing is largely manufactured up of in-up ring, in-down ring and outside ring, so balls and spacers can be straight discharged into the upper and reduce raceway. In line with tension situations, bearings are arranged to two rows of balls of various diameter. This assembly is quite convenient. Angle of each upper and decrease raceway is 90??so bearings can bear significant axial force and resultant torque. Bearing desires distinctive style when radial force is 0.one times more substantial compared to the axial force. Huge in sizes and attributes compact in style and design, bearings are notably application in dealing with equipments requiring medium over diameter, such as tower crane and mobile crane.

single row cross roller slewing ring is mainly manufactured up of within and outdoors rings. It capabilities compact in layout, light in fat, little in assembling clearance, and higher in putting in precision. As the rollers are crossed arranged by 1:one, it can be ideal for large precision mounting and capable to bear axial force, radial force and resultant torque simultaneously. This series single row crossed roller slewing bearing have extensively application in lift transport aircraft, construction machinery, and military solutions.

one. Qualified gears manufacturer

two.Expert in Cooperate with significant Providers

three. Qualified gears Engineering Capability

4.Stable gears High-quality

5.Affordable gears Charges

6.Smaller gears Orders Accepted

7.Steady gears quality enhancements

eight. Large gears quality Functionality

9.Short gears lead time and shipment

ten.Professional gears service

We can create 6 models of slewing bearings in a variety of specifications with diameters ranging from 400 mm to 5050 mm. Our merchandise show every day to be vital structural and connection aspects used in wind turbines, excavators, mobile cranes, harbor and shipyard cranes, robots, health-related scanners and generally mechanical engineering.

High-quality Management:

Excellent could be the vital to our accomplishment. We’re committed to obtaining customers’ satisfaction by supplying superior quality products and services.

We be certain that our in depth excellent management method is in accordance with ISO9001 typical and is performed correctly.

In pursuit of high-quality raw elements, we go through a stringent verification and assortment course of action to choose the very best suppliers of forged rings and various parts in China. If essential, we are able to also apply extra large-diameter forged rings created by ThyssenKrupp in Germany.

Cranes are uniquely constructed, which suggests the slewing ring bearing is an crucial element of its design and style. High-quality and precision during the manufacturing system.

Gear transmission refers to your gadget that transmits motion and power in the gear pair. It is the most extensively employed mechanical transmission approach in present day products. Its transmission is extra correct, higher efficiency, compact construction, reliable operation and extended service existence.Our gears may be heat treated, hardened, oil immersed in line with purchaser demands.The gear is widely used in industry, vehicle, power equipment, motor, bicycle, electrombile.

Nylon gear racks is utilized on sliding gate, There is certainly steel core within it. we exported to Europe in significant quantity.

There’s steel core within the nylon gear rack.You will find two goods available. You will discover four eye(4 bracket is light sort) and 6 eyes(six brackets is hefty form).Every single piece of nylon gear rack with screw set

Producer supplier exporter of gear rack

We exported gear rack in massive quantity to Europe, America, Australia, Brazil, South Africa, Russia and so on. There is common gear rack obtainable and in addition exclusive gear rack as per your drawing or samples. Our gear racks developed by CNC machines

There exists many sizes of steel gears rack for sliding door also. M4 8?¨¢30, M4 9?¨¢30, M4 10?¨¢30, M4 11?¨¢30, M4 12?¨¢30, M4 20?¨¢20, M4 22?¨¢22, M6 30?¨¢30 and so forth

For M4 8?¨¢30, M4 9?¨¢30, M4 10?¨¢30, M4 11?¨¢30, M4 12?¨¢30, 1M length have three bolt,nut, washer sets and just about every 4pcs or 6pcs packed into carton box then place into steel pallet. For M4 8?¨¢30, M4 9?¨¢30, M4 10?¨¢30, M4 11?¨¢30, M4 12?¨¢30, 2M length have 4 bolt,nut, washer sets.

We will also provide the sliding gate aspect such as sliding door pulley, wheel, roller and so forth. Please kindly test  and allow me know your detail request

and allow me know your detail request

In the event you will need 2M or 3M, or any other length, we are able to make as per your requests

Nearly all of our buyer will send us drawing and we are able to generate as per your drawing or sample.

We produce Module M1-M8 racks, CP and DP British typical racks. The utmost length on the rack is 2 meters. Our solutions have already been broadly used in several fields such as automated doors, window openers, engraving machines, lifters, escalators, automated warehousing, meals machinery, electrical power tools, machine resources, precision transmission, and so on.

We exported gear rack in major amount to Europe, America, Australia, Brazil, South Africa, Russia etc. There is certainly conventional gear rack accessible as well as particular gear rack as per your drawing or samples. Our gear racks created by CNC machines.

Our gear racks are made use of for window machine, engraving machine, lift machine, opener rack, CNC machine, automobile, industrial usage so on.

1) Our gear rack is produced as per DIN specifications by CNC machine

two) The strain angle: 20??/14.5??

3) Module: M0.4-M36/DP1-DP25

four) The utmost length is usually 3500mm

5) The material is usually Q235, C45, SS304, SS316L, aluminum, copper, nylon and so on.

Our gear racks are applied for window machine, engraving machine, lift machine, opener rack, CNC machine, car, industrial usage so on.

Industrial Gear Rack

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

We will also provide Building lift gear rack,American conventional gears racks,steel gear rack,helical gear rack,flexible gear racks,power steering rack,steering gear rack ,stainless steel gear rack ,round rack gear ,nylon gear rack ,spur gear rack ,boston gear rack ,audia gear rack ,gears racks ,rack and pinion gear

1. Wealthy industry working experience considering that 1988.

2. Broad organize product line, which include plastics sheet/rod/parts/accessories: MC NYLON, OIL NYLON, POM, UHMW-PE, PU, PETP, Pc, PTFE, PVDF, PPS, PEEK, PAI, PI, PBI ect.

three. Manufacture, style and design and processing services as per your demand

one. Good Tensile power;

2. Higher effect and notching impact power;

3. Higher heat deflection temperature ;

four. Substantial strength and stiffness;

five. Excellent glide and limp property characters;

6. Superior chemical stability against natural solvents and fuels;

7. Resistant to thermal aging (applicable temperature amongst -50??C and 110??C;

eight. Dimension alternation by humidity absorption have to be regarded as;

Shaft sleeve, bearing bush, lining, lining plate, gear;

Worm gear, roller copper manual rail, piston ring, seal ring, slide block;

Spheric bowl, impeller, blade, cam, nut, valve plate,

Pipe, stuffing box, rack, belt pulley, pump rotor, and so on.rack pinion gear for elevator in stockoperator Steel and Nylon gear rack SPUR GEAR RACK AND PINION nylon gear rack iron gear rack We warmly welcome consumers each in your house and abroad to contact us to negotiate company, exchange facts and cooperate with us.

IN CNC GEAR Manufacturing PLANT, More than Ten OF GEARS Producing LINES:

Gear turning,hobbing,shaving,shaping,grinding,slotting,

broaching , we?¡¥ve created substantial investment..

Our higher precision tools can continue to keep a higher top quality prodcuts.CAN DO Each of the HEATING Method: CARBURIZING/CARBONITRIDING/QUENCHING/NORMALIZING/ANNEALING/REHEATING

two sets of UBE series multi-purpose chamber(IQ) Japan furnace;

2 sets of German Ipsen ambiance furnace lines.

9 ton of steel capacity for heat treatment method on a daily  basis.

basis.

Minimal CARBON STEEL METAL GEARS Tiny,Smaller STEEL METAL SPUR GEARS!

From basic 2-axis turning to 7-axis, turn-mill-drill CNC Swiss-type machines, we are outfitted which has a complete line of CNC tools in the following manufactures:

molding machines/ stamping machines

automatic lathe machines/ spring machines.

Surface: as your necessity

OUR CLEANSES

one.Material:C 45# steel ,stainless steel or other expected materials.

two.Sprockets may be created in accordance the customer?¡¥s drawings

Our major items: Ultra higher molecular bodyweight polyethylene, MC nylon, PA6, POM, HDPE, PP,PU, Computer, PVC, ABS, ACRYLIC,PTFE, PEEK, PPS,PVDF.

3.Heat treatment method: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on according the specifications..

four. Inspection: All objects are checked and tested thoroughly throughout every single operating method and following manufacturing are going to be reinspected.

Gear transmission refers towards the device that transmits motion and electrical power through the gear pair. It can be by far the most broadly utilised mechanical transmission approach in modern day equipment. Its transmission is additional correct, large efficiency, compact framework, trusted operation and extended service existence.

Our gears may be heat taken care of, hardened, oil immersed in accordance to buyer needs.

The gear is broadly applied in field, vehicle, electrical power equipment, motor, bicycle, electrombile.

Large PRECISION Custom SPUR HELICAL GEAR

Spur gears are broadly accepted as the most effective style of gearing remedy, once the application of transmitting energy and uniform rotary movement from one parallel shaft to a further is needed. Established by the center distance, spur gears build a steady working speed drive. This drive pace could be decreased or improved from the variable amount of teeth that exist inside the driving gear.

Sort: BEVEL GEAR

Manufacturing Strategy: Lower Gear

Toothed Portion Form: Bevel Wheel

Primary Client: Electrical tool factory

Export Markets: International

Modest PINION STEEL DOUBLE SPUR GEAR

Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing,

ELECTROPLATING, ANODIZING Etc.

Black oxide coating, painting, powdering, shade zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic,We can make customers?¡¥ satisfactory products according to the samples or drawings presented by shoppers. For that completion of a product or service, we also will need to know his material, heat treatment prerequisites and surface therapy necessities. We’re a factory with 40 many years of manufacturing experience, welcome to seek advice from.

we utilize the latest machining technologies by using a broad range of abilities to meet your demands. Our manufacturing services consist of 3-5 axis milling, lathes, grinding, and so on, and state on the art metrology. With these machines, we make complex elements during the most effective and exact way. Our manufacturing capabilities allow us to create your component from prototype to mass manufacturing for the most exact of jobs.

gear box,gearbox,automatic gearbox,gearbox components,gearbox repairs,steering gear box,reduction gearbox,worm gear,motor gearbox,auto gearbox,gearbox store,worm gear box,gearbox producers,box gear,planetary gear box,modest gearbox,helical gearbox,dc gear motor,gear motor,gear reducer,helical gear box,automobile gear box,gearbox gears,transmission gearbox,reduction gear box,planetary gear,gearbox transmission,auto transmission,used gearbox for sale,worm gear motor,made use of gearbox,worm gear reducer,transmission gears,planetary gear reducer,substitute gearbox,mini gearbox

PTO is often a splined drive shaft that’s normally positioned on tractors or may be applied to supply energy backup to a separate machine.

The PTO shafts that we give comprises of two carden joints and telescopic couplings. Tractor side and implement side are the two ends of these shafts. The implement side includes a shear bolt form yoke and includes security guards.

one, Materials: Carbon steel/ stainless steel/ aluminum alloy/ copper/bronze/iron/etc.

2, OEM or as per sample or drawing

3, Surface: Blacking, Polishing, Anodize, Chrome plating, Zinc plating, Nickel plating, Tinting, Power coating etc.

four, Course of action: Forging, Stamping, Machining, Metalworking, Sheet Metal Bending, Surface Remedy, Heat Therapy, Gridding, Milling, wire EDM, Linear Cutting etc.

5, Precision: OEM/ODM is accessible

The power take-off (PTO) is a sophisticated mechanism, permitting implements to draw power through the engine and transmit it to an additional application. It will work like a mechanical gearbox which can be mounted about the vehicle?¡¥s transmission.

CHINA FACTORY LARGEBRASS MILLING AND ALUMINUM CASTING MOLDS Producer

We are the producer to produce Japanese tractor spare elements,primarily for kubota,iseki,yanmar,and so on.

We’re supplying and exporting Japanese tractor parts as the following designs

¡§C Kubota model: B5000, B7000, B1400, B1600

¡§C YM model: YM F14, YM1100, YM F1401/1901,YM F35

¡§C Iseki model: TX1300, TX1410,TU1400-1500

UNIVERSAL JOINT MECHANICAL COMPORENTS MACHINE TRACTOR PTO SHAFT Components UNIVERSAL JOINT

Tubes or Pipes

We?¡¥ve by now got Triangular profile tube and Lemon profile tube for every one of the series we give.

And we’ve got some star tube, splined tube together with other profile tubes but only for a particular sizes.

We specializing from the production of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and much more.

5 End yokes

We have received 13 kinds of splined yokes and eight forms of plain bore yokes. I’ll propose the usual sort for the reference.

You’ll be able to also send drawings or images to us for those who cannot discover your item in our catalog.

six Safety devices or clutches

I will attach the specifics of security gadgets to your reference. We’ve by now have Absolutely free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

7 For just about any other additional unique needs with plastic guard, connection system, colour of painting, package, and so on., please feel free to allow me know.

The Gearboxes are intended for connecting gear pumps to farm tractor electrical power consider offs (PTO). Output velocity of energy get offs is 540rpm which may be in contrast using the suitable operating speeds of hydraulic pumps. Unique input operating speeds could also be appropriate,offered the PTO gearbox output velocity does not exceed  3000 rpm.

3000 rpm.

Housing

Produced in shell-cast aluminum or in large mechanical resistance cast iron.

Torques

The torque figures stated from the technical charts of the many PTO Gearboxes refer to steady duty cycles. Torques below intermittent doing work disorders might be exceeded by 20%.

Servicing

Please check the oil level via the specific oil window each and every 50 hrs. Functioning temperatures need to not exceed 120 degrees celcius below continuos duty cycle.

1. Tubes or Pipes

We have by now received Triangular profile tube and Lemon profile tube for all of the series we present.

And we’ve got some star tube, splined tube and also other profile tubes necessary by our prospects (to get a certain series). (Please observe that our catalog doesnt incorporate each of the goods we make)

If you would like tubes aside from triangular or lemon, please deliver drawings or images.

two.End yokes

We’ve acquired several kinds of speedy release yokes and plain bore yoke. I will propose the usual variety to your reference.

It is possible to also send drawings or images to us should you are not able to come across your item in our catalog.

3. Security devices or clutches

I will attach the details of safety units to your reference. We’ve already have Totally free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

four.For just about any other extra unique prerequisites with plastic guard, connection process, colour of painting, package deal, etc., please come to feel no cost to allow me know.

Capabilities:

one. We now have been specialized in creating, manufacturing drive shaft, steering coupler shaft, universal joints, which have exported on the USA, Europe, Australia etc for a long time

2. Application to all varieties of standard mechanical problem

three. Our goods are of substantial intensity and rigidity.

4. Heat resistant & Acid resistant

5. OEM orders are welcomed

The Gearboxes are built for connecting gear pumps to farm tractor electrical power take offs (PTO).Output velocity of electrical power take offs is 540rpm which can be in contrast together with the suitable operating speeds of hydraulic pumps.Distinctive input operating speeds also can be ideal,offered the PTO gearbox output pace isn’t going to exceed 3000 rpm.

Gears

Made in Steel UNI 18 PCR M03.Stub teeth guarantee very substantial resistance and run very quietly.

Shafts

Manufactured in steel UNI 16 CRN4.They are coupled with splined gears and are intended to stand the torque values stated in the catalogue.

Lubrication

90 gear oil must be put in the pto gearbox prior to use, change the oil after the first 60-80 hours and then just about every 12 months or 1500 hours which ever falls first.

Upkeep

Please examine the oil degree through the distinctive oil window each and every 50 hours.Functioning temperatures really should not exceed 120 degrees celcius beneath continuos duty cycle.

Producer supplier exporter of bush chains

We specializing within the manufacturing of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and much more.

Taper Lock Pulley V Belt Pulley

We present higher top quality Taper Lock Pulley V Belt Pulley in aggressive price

v pulley, v belt pulleys, taper lock pulley,v belt pulleys ,v pulley,v groove pulleys,v groove belt pulley,taper lock pulley,taper lock v belt pulleys,taper lock bushing pulley,taper lock pulleys/ taper bore pulley,substantial v belts pulley,double v belts pulley,cast iron v belt pulleys belt pulley,variable pace v belt pulley,v belt pulley split pulley,cast iron v belts pulley

V-BELT PULLEY INTRODUCE:

V- belt pulley of different varieties ( based on sort and width of belts). The material made use of is cast iron EN-GJL-250 UNI EN 1561, and for only a few forms it’s steel C45 E UNI EN 10083-1. They’ve got a little prebore that may be machined based on customers?¡¥ specifications. Additionally probably the most popular sorts are available also with taperlock bore.

V BELT PULLEY Specifications

a) Vbelt pulley for taper bushing: SPZ, SPA, SPB, SPC

b) vpulley Adjustable pace V-belt pulleys and variable pace pulleys c) Flat belt pulleys and conveyor belt pulleys

?¡è AMERICAN Regular:

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

?¡è We are able to Present THE RANG Size DIAMETER 62MM~2000MM

d) Sheaves for 3L, 4L or perhaps a, and 5L or B belts: AK, AKH,2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK e) Adjustable sheaves: poly V-pulley, multi-pitch H, L, J, K and M

Quality Timing Pulley Light Fat Industrial Nylon Plastic Pulley V Belt Pulley

1.Materials: Aluminium alloy,Carton steel, Cast iron, Stainless steel timing belt pulleys

2.Surface treament: Anodizing, Blackening, Zinc Plating, Phosphatiing

3. Teeth Variety from 9 to 216; O.D. from 10mm to 1000mm;

4. Timing belt pulleys MXL, XL, L, H and XH; T2.5, T5, T10, AT5,AT10; 3M,5M,8M and 14M S3M, S5M, S8M, 14MGT, 8MGT, RPP8M

5. Taper bush and polit bores

six. Timing pulley bar 3M,5M,8M,MXL,XL,L T2.5 T5 T10 AT5 and AT10

1) Solid design and style, appropriate for hefty lifting.

2) The bearing housing and steel tube are assembled and welded which has a concentric automated.

car

4) The bearing end is constructed to make certain the roller shaft and bearing is usually firmly connected.

air compressors

6) Roller and supporting components/materials are manufactured to DIN/ AFNOR/ FEM/ ASTM/ CEMA typical.

belt conveyor drive drum pulley

About roller,we can make gravity conveyor roller,steel conveyor roller,driving roller,light middle duty conveyor roller,o-belt tapered  sleeve roller,gravity tapered roller,polymer sprocket roller and so on. Additional details, please contact us.

sleeve roller,gravity tapered roller,polymer sprocket roller and so on. Additional details, please contact us.

Is usually employed for tractors

three) Cutting on the steel tube and bearing is carried out with all the use of a digital auto device/machine/equipment..

garden cutter

5) Fabrication from the roller is effected by an auto gadget and 100% examined for its concentricity.

welcome your inquiries

seven) The casing is produced with highly composite, anti corrosive alloy.

1) European standards :

a) V-belt pulley for taper bushing: SPZ, SPA, SPB, SPC; as much as ten grooves

b) Adjustable pace V-belt pulleys and variable velocity pulley

c) Flat belt pulleys and conveyor belt pulleys

2) American requirements:

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

d) Sheaves for 3L, 4L or maybe a, and 5L or B belts: AK, AKH, 2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK

e) Adjustable sheave: poly V-pulley, multi-pitch H, L, J, K and M

Why Choose Us

1) Practical experience in casting for more than 15 years and served shoppers all around the world.

two) Regular materials based on technical drawing

3)Secure top quality

four) On-time delivery

five) Aggressive rate and great support

6) Positive purchaser feedback from domestic and worldwide market place

7) Global advanced-level equipment for example CNC, numerical lathes, furnance, welding

tools, CMM and detect &testing equipment we used to be sure our product?¡¥s quality.

8) OEM service, your demand is our pursued.

9) ISO9001:2008 and TS16949 top quality control

10) Typical: ASTM BS DIN etc

Bush Chains

As one of major motor coupling manufacturers, suppliers and exporters of mechanical goods, We supply bush chains and many other merchandise.

Producer supplier exporter of bush chains

We specializing during the production of Agricultural Gearbox, PTO Shafts, Sprockets, Fluid Coupling, Worm Gear Reducers, Gears and racks, Roller Chains, Sheave and Pulleys, Planetary Gearboxes, Timing Pulleys, Shaft Collars and much more.

We’ve got exported our products to clientele about the planet and earned a great track record due to the fact of our superior product or service good quality and after-sales service.

We warmly welcome customers both at home and abroad to get in touch with us to negotiate business enterprise, exchange facts and cooperate with us.

we’re a single professional chain factory ,generating both standard roller chains and nonstandard chains,A and B series roller chain,straight side roller chain,H series of roller chain, motocycle chain ,other roller chain .

Zinc-plated,Nickel-plated,Docromet-plated etc.Comply with the normal of ANSI,ISO,DIN,BSetc.and also with diverse attachment. Top quality may be guaranteed!

Our items have passed ISO:9001 high quality management system and stand the end users?¡¥ ordeal. We dedicate ourselves to manufacture the high-quality goods with competitive charges, we know the industries properly, consequently from layout to materials selection, until manufacturing technique is as much as the substantial normal, meanwhile our preparing team and international group will make certain the punctual delivery.

Timing Bush Chains for Car Engine

1. Materials: Stainless steel / Alloy steel / Manufactured to buy

two. Surface Treatment method: Zinc-Plated / Nickel-Plated / Shot Peening / Blackening

3. Chain Form: Roller chains, Drive chains,Conveyor Chains, Hollow Pin Chains,Welded chains, Steel Pin Chains, Palm oil chains,Sugar Mill Chains.ect.

Transmission Precision Bush Chains

A lifting chain is rigging tools made use of with hoists, cranes, and winches in material managing applications. An arrangement named a chain sling is usually utilized because the lifting part connecting the hoisting gadget on the load. A chain sling consists of a master hyperlink and 1 or a lot more chain legs with hooks.

Transmission Precision Roller and Bush Chains

Utilised industrial transmission roller chains;Industrial and agricultural machinery, such as conveyors,wire¡§C and tube¡§Cdrawing machines, printing presses, cars, motorcycles, and bicycles.It consists of a series of quick cylindrical rollers held together by side links.It really is an easy, trustworthy, and efficient suggests of power transmission.

High-quality orientation: Over the average, primarily exported to USA, Europe, Asia and so forth.

Strictly according: ISO/ANSI/DIN normal.

Price tag orientation: Price-performance ratio is incredibly higher.

Stainless Steel Hollow Pin Bush Chains Conveyor Chain Roller transmission bush double flex chain Side Bow Chain The Sleeve Chain/ Bush  Chain/motorcycle chain large strength bucket elevator conveyor bush roller chain

Chain/motorcycle chain large strength bucket elevator conveyor bush roller chain

We are specialist supplier of chains

Multi strand sizes out there; as much as 5 strand, for select size regular attachment accessible

ten.Chains from 04b~16b are with spring clip, other are riveted; cottered style

is accessible for size 80 to 240

Stainless steel chain and nickel plated chains is obtainable; specific design also offered

(i.e., oven conveyor) and we will develop as per materials your requests, ordinarily stainless steel chains material is SS304, in case you need SS316 or SS316L and so forth. it is actually obtainable too

This bush chain which has a diminished variety of parts, has proved to be particularly thriving in large duty, substantial abrasion application the place lubrication will not be probable. Our steel bush chains happen to be proving efficiency in mill duty centrifugal discharge elevators inside the more difficult applications encountered inside the cement market.

China factory Ball Mill Segment Ring Gear Bull 35CrMo Casting Steel Custom Large Diameter Outer Spur Large Ring Gear gear patrol

Product Description

Key attributes

Other attributes

Applicable Industries

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Construction works , Energy & Mining, Other

Weight (KG)

1200

Showroom Location

None

Video outgoing-inspection

Provided

Machinery Test Report

Provided

Marketing Type

New Product 2571

Warranty of core components

1 Year

Core Components

Gear

Place of CHINAMFG

ZheJiang , China

Condition

New

Warranty

1.5 years

Shape

Spur

Brand Name

TS

Material

Steel

Product Name

Large Diameter Ring Gears

Process

Milling,hobbing

Surface treatment

Grinding

Heat treatment

Q&T

Application

Industry machinery,transmission equipment

Standard

DIN ANSI ISO

Certificate

ISO 9001:2015

Module No.

Customized

Size

Customer’s Drawing

Quality

High level

Packaging and delivery

Packaging Details

Package adapting to CHINAMFG transport

Port

HangZhou, ZheJiang

Supply Ability

Supply Ability

15 Piece/Pieces per Month steel large spur gears

OUR WORKSHOPS

OUR EQUIPMENTS

Technology Process

|

Material |

Carbon steel,Alloy steel |

||

|

Structure |

Forging,casting |

||

|

Type of gear |

spur gear,helical gear,Planetary Gear |

||

|

Heat treatment |

Quenching and tempering |

||

|

Process |

forging, rough machining, QT, finish machining |

||

|

Main equipments |

hobbing,CNC machine |

||

|

Module |

up to 200 |

||

|

Precision of gear |

Grinding ISO Grade 5-7 & Hobbing ISO Grade 8-9 |

||

|

Inspection |

Raw material inspection, UT,physical property test,dimension inspect |

||

|

Application |

Mining machinery, mill, kiln and other equipment |

||

OUR CERTIFICATE

OUR CUSTOMER FEEDBACK

CONTACT

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industry |

|---|---|

| Hardness: | Hb190-Hb300 |

| Gear Position: | External Gear |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you calculate the efficiency of a spur gear?

Calculating the efficiency of a spur gear involves considering the power losses that occur during gear operation. Here’s a detailed explanation:

In a gear system, power is transmitted from the driving gear (input) to the driven gear (output). However, due to various factors such as friction, misalignment, and deformation, some power is lost as heat and other forms of energy. The efficiency of a spur gear represents the ratio of the output power to the input power, taking into account these power losses.

Formula for Calculating Gear Efficiency:

The efficiency (η) of a spur gear can be calculated using the following formula:

η = (Output Power / Input Power) × 100%

Where:

η is the efficiency of the gear system expressed as a percentage.

Output Power is the power delivered by the driven gear (output) in the gear system.

Input Power is the power supplied to the driving gear (input) in the gear system.

Factors Affecting Gear Efficiency:

The efficiency of a spur gear is influenced by several factors, including:

- Tooth Profile: The tooth profile of the gear affects the efficiency. Well-designed gear teeth with accurate involute profiles can minimize friction and power losses during meshing.

- Lubrication: Proper lubrication between the gear teeth reduces friction, wear, and heat generation, improving gear efficiency. Insufficient or inadequate lubrication can result in increased power losses and reduced efficiency.

- Gear Material: The selection of gear material affects efficiency. Materials with low friction coefficients and good wear resistance can help minimize power losses. Higher-quality materials and specialized gear coatings can improve efficiency.

- Gear Alignment and Meshing: Proper alignment and precise meshing of the gear teeth are essential for optimal efficiency. Misalignment or incorrect gear meshing can lead to increased friction, noise, and power losses.

- Bearing Friction: The efficiency of a gear system is influenced by the friction in the bearings supporting the gear shafts. High-quality bearings with low friction characteristics can contribute to improved gear efficiency.

- Load Distribution: Uneven load distribution across the gear teeth can result in localized power losses and reduced efficiency. Proper design and gear system configuration should ensure even load distribution.

Interpreting Gear Efficiency:

The calculated gear efficiency indicates the percentage of input power that is effectively transmitted to the output. For example, if a gear system has an efficiency of 90%, it means that 90% of the input power is converted into useful output power, while the remaining 10% is lost as various forms of power dissipation.

It’s important to note that gear efficiency is not constant and can vary with operating conditions, lubrication quality, gear wear, and other factors. The calculated efficiency serves as an estimate and can be influenced by specific system characteristics and design choices.

By considering the factors affecting gear efficiency and implementing proper design, lubrication, and maintenance practices, gear efficiency can be optimized to enhance overall gear system performance and minimize power losses.

What is the lifespan of a typical spur gear?

The lifespan of a typical spur gear can vary significantly depending on several factors. Here’s a detailed explanation:

The lifespan of a spur gear is influenced by various factors, including:

- Operating Conditions: The conditions under which the spur gear operates greatly impact its lifespan. Factors such as the magnitude and frequency of the applied loads, operating temperature, speed, and lubrication quality play a significant role. Gears operating under heavy loads, high speeds, or harsh environments may experience higher wear and fatigue, potentially reducing their lifespan.

- Material Selection: The material used for constructing the spur gear affects its durability and lifespan. Spur gears are commonly made from materials such as steel, cast iron, bronze, or polymer composites. The specific material properties, including hardness, strength, and resistance to wear and corrosion, influence the gear’s ability to withstand the operating conditions and determine its lifespan.

- Quality of Manufacturing: The quality of manufacturing processes and techniques employed during the production of the spur gear can impact its lifespan. Gears manufactured with precision, accurate tooth profiles, and proper heat treatment are more likely to have longer lifespans compared to those with manufacturing defects or poor quality control.

- Lubrication and Maintenance: Proper lubrication is crucial for reducing friction, wear, and heat generation in spur gears. Regular maintenance practices, including lubricant replacement, gear inspections, and addressing any issues promptly, can significantly extend the lifespan of the gears. Inadequate lubrication or neglecting maintenance can lead to premature wear and failure.

- Load and Stress Distribution: The design and configuration of the gear system affect the load and stress distribution on the spur gears. Proper gear design, including tooth profile, number of teeth, and gear arrangement, helps ensure even load distribution and minimizes localized stress concentrations. Well-designed supporting components, such as bearings and shafts, also contribute to the overall lifespan of the gear system.

It is challenging to provide a specific lifespan for a typical spur gear since it depends on the aforementioned factors and the specific application. Spur gears can have lifespans ranging from several thousand to millions of operating cycles. Industrial gear systems often undergo regular inspections and maintenance, including gear replacement when necessary, to ensure safe and reliable operation.

It’s important to note that gear lifespan can be extended through proper care, maintenance, and adherence to recommended operating parameters. Regular inspections, monitoring of gear performance, and addressing any signs of wear or damage promptly can help maximize the lifespan of spur gears.

When assessing the lifespan of spur gears for a particular application, it is advisable to consult manufacturers, industry standards, and experts with expertise in gear design and maintenance for accurate estimations and recommendations.

What industries commonly use spur gears?

Spur gears find wide applications across various industries due to their simplicity, efficiency, and versatility. Here’s a detailed explanation of the industries that commonly use spur gears:

- Automotive Industry: The automotive industry extensively utilizes spur gears in various components and systems. They are commonly found in gearboxes, differentials, transmission systems, and engine timing mechanisms. Spur gears play a crucial role in transferring power and rotational motion between the engine, wheels, and other drivetrain components.

- Machinery and Manufacturing: Spur gears are widely employed in machinery and manufacturing equipment across different sectors. They are used in conveyor systems, machine tools, printing presses, textile machinery, packaging machinery, and a variety of industrial applications. Spur gears facilitate power transmission and motion control in these systems.

- Power Generation: Spur gears are essential in power generation systems such as wind turbines, hydroelectric turbines, and steam turbines. They are used to transmit power from the rotor to the generator, converting the rotational motion of the turbine blades into electricity. Spur gears enable efficient power transfer in these renewable energy systems.

- Robotics and Automation: Spur gears have significant applications in robotics and automation systems. They are used in robotic joints, actuators, and drive systems to control motion and transmit torque accurately and efficiently. Spur gears enable precise movement and force transmission in robotic applications.

- Aerospace and Aviation: The aerospace and aviation industries utilize spur gears in various applications. They can be found in aircraft landing gear systems, engine components, flight control systems, auxiliary power units (APUs), and other critical equipment. Spur gears play a vital role in transmitting power and controlling movement in these aerospace systems.

- Marine and Shipbuilding: Spur gears are commonly used in the marine and shipbuilding industry. They find applications in propulsion systems, winches, steering mechanisms, and other equipment that require torque transmission and speed control. Spur gears enable efficient power transfer and maneuverability in marine vessels.

- Appliances and Household Equipment: Spur gears are present in numerous household appliances and equipment. They are used in washing machines, dishwashers, mixers, food processors, garage door openers, and many other appliances that require rotational motion and power transmission. Spur gears facilitate the efficient operation of these household devices.

- Power Tools: Spur gears are widely utilized in power tools such as drills, saws, grinders, and sanders. They enable the transmission of power from the motor to the tool’s cutting or grinding components, ensuring efficient and controlled operation. Spur gears contribute to the functionality and performance of power tools.

- Medical Equipment: Spur gears are used in various medical devices and equipment. They can be found in imaging systems, surgical robots, medical pumps, and other applications that require precise motion control and torque transmission. Spur gears play a critical role in the functioning of medical equipment.

- Clocks and Watches: Spur gears are a fundamental component in mechanical clocks and watches. They are responsible for accurate timekeeping by transferring rotational motion from the mainspring or oscillator to the hour, minute, and second hands. Spur gears have historical significance in timekeeping mechanisms.

These are just a few examples of the industries where spur gears are commonly used. Their simplicity, reliability, and efficiency make them a popular choice in a wide range of applications, enabling power transmission, motion control, and precise operation in diverse industrial sectors.

editor by Dream 2024-05-08

China supplier Low Noises Worm and Wormwheel OEM Steel Rack Spur Gear with high quality

Product Description

My advantages:

1. High quality materials, professional production, high-precision equipment. Customized design and processing;

2. Strong and durable, strong strength, large torque and good comprehensive mechanical properties;

3. High rotation efficiency, stable and smooth transmission, long service life, noise reduction and shock absorption;

4. Focus on gear processing for 20 years.

5. Carburizing and quenching of tooth surface, strong wear resistance, reliable operation and high bearing capacity;

6. The tooth surface can be ground, and the precision is higher after grinding.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Cast Steel |

| Type: | Worm And Wormwheel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you calculate the efficiency of a spur gear?

Calculating the efficiency of a spur gear involves considering the power losses that occur during gear operation. Here’s a detailed explanation:

In a gear system, power is transmitted from the driving gear (input) to the driven gear (output). However, due to various factors such as friction, misalignment, and deformation, some power is lost as heat and other forms of energy. The efficiency of a spur gear represents the ratio of the output power to the input power, taking into account these power losses.

Formula for Calculating Gear Efficiency:

The efficiency (η) of a spur gear can be calculated using the following formula:

η = (Output Power / Input Power) × 100%

Where:

η is the efficiency of the gear system expressed as a percentage.

Output Power is the power delivered by the driven gear (output) in the gear system.

Input Power is the power supplied to the driving gear (input) in the gear system.

Factors Affecting Gear Efficiency:

The efficiency of a spur gear is influenced by several factors, including:

- Tooth Profile: The tooth profile of the gear affects the efficiency. Well-designed gear teeth with accurate involute profiles can minimize friction and power losses during meshing.

- Lubrication: Proper lubrication between the gear teeth reduces friction, wear, and heat generation, improving gear efficiency. Insufficient or inadequate lubrication can result in increased power losses and reduced efficiency.

- Gear Material: The selection of gear material affects efficiency. Materials with low friction coefficients and good wear resistance can help minimize power losses. Higher-quality materials and specialized gear coatings can improve efficiency.

- Gear Alignment and Meshing: Proper alignment and precise meshing of the gear teeth are essential for optimal efficiency. Misalignment or incorrect gear meshing can lead to increased friction, noise, and power losses.

- Bearing Friction: The efficiency of a gear system is influenced by the friction in the bearings supporting the gear shafts. High-quality bearings with low friction characteristics can contribute to improved gear efficiency.

- Load Distribution: Uneven load distribution across the gear teeth can result in localized power losses and reduced efficiency. Proper design and gear system configuration should ensure even load distribution.

Interpreting Gear Efficiency:

The calculated gear efficiency indicates the percentage of input power that is effectively transmitted to the output. For example, if a gear system has an efficiency of 90%, it means that 90% of the input power is converted into useful output power, while the remaining 10% is lost as various forms of power dissipation.

It’s important to note that gear efficiency is not constant and can vary with operating conditions, lubrication quality, gear wear, and other factors. The calculated efficiency serves as an estimate and can be influenced by specific system characteristics and design choices.

By considering the factors affecting gear efficiency and implementing proper design, lubrication, and maintenance practices, gear efficiency can be optimized to enhance overall gear system performance and minimize power losses.

What is the purpose of using spur gears in machinery?

In machinery, spur gears serve several important purposes due to their unique characteristics and capabilities. Here’s a detailed explanation of the purpose of using spur gears in machinery:

- Power Transmission: Spur gears are primarily used for power transmission in machinery. They transfer rotational motion and torque from one shaft to another, allowing machinery to perform various tasks. By meshing the teeth of two or more spur gears together, power can be transmitted efficiently and reliably throughout the machinery.

- Speed Reduction or Increase: Spur gears enable speed reduction or increase in machinery. By combining gears with different numbers of teeth, the rotational speed can be adjusted to match the desired output speed. For example, using a larger gear driving a smaller gear can increase the speed output while reducing the torque, while the opposite arrangement can decrease the speed while increasing the torque.

- Torque Amplification: Spur gears can amplify torque in machinery. By using gears with different numbers of teeth, the torque can be adjusted to match the required output. For example, using a smaller gear driving a larger gear can increase the torque output while reducing the speed, while the opposite arrangement can decrease the torque while increasing the speed.

- Directional Control: Spur gears provide directional control in machinery. By meshing gears with opposite orientations, the rotational direction of the driven shaft can be reversed or changed. This directional control is crucial for machinery that requires bi-directional motion or needs to change the direction of operation.

- Mechanical Advantage: Spur gears offer a mechanical advantage in machinery. By utilizing gear ratios, spur gears can multiply or divide the force exerted on the input shaft. This mechanical advantage allows machinery to generate higher forces or achieve precise movements with reduced effort.

- Precision Positioning: Spur gears facilitate precise positioning in machinery. The accurate tooth engagement of spur gears ensures precise control over rotational motion, making them suitable for applications that require precise positioning or synchronization of components. Machinery such as CNC machines, robotics, and automation systems often rely on spur gears for accurate movement and positioning.

- Compact Design: Spur gears have a compact design, making them suitable for machinery with space constraints. They can be arranged in-line, parallel, or at right angles, allowing for efficient power transmission in tight spaces. Their compactness enables machinery to be designed with smaller footprints and optimized layouts.

- Reliability and Durability: Spur gears are known for their reliability and durability in machinery. The direct tooth engagement and uniform load distribution result in efficient power transmission with reduced wear and stress concentration. When properly lubricated and maintained, spur gears can withstand heavy loads and operate reliably over extended periods.

- Cost-Effectiveness: Spur gears are often cost-effective in machinery applications. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings. The availability of spur gears in various sizes and materials further enhances their cost-effectiveness.

By utilizing spur gears in machinery, engineers and designers can achieve efficient power transmission, speed and torque control, directional versatility, mechanical advantage, precise positioning, compact design, reliability, durability, and cost-effectiveness. These advantages make spur gears a popular choice in a wide range of machinery applications across industries.

What are the benefits of using a spur gear mechanism?

Using a spur gear mechanism offers several benefits in various applications. Here’s a detailed explanation of the advantages of using a spur gear mechanism:

- Simplicity: Spur gear mechanisms are relatively simple in design, consisting of cylindrical gears with straight teeth. Their simplicity makes them easy to manufacture, assemble, and maintain. They have fewer components compared to other types of gear mechanisms, resulting in lower complexity and potentially reduced costs.

- Efficiency: Spur gears exhibit high efficiency in power transmission. The teeth of spur gears mesh directly, resulting in minimal energy loss during transmission. The simplicity of their tooth profile allows for efficient power transfer, making them an energy-efficient choice for many applications.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in-line, parallel to each other, or at right angles using additional components such as bevel gears. This flexibility in arrangement allows for efficient power transmission in tight spaces.

- Versatility: Spur gears are versatile and can be used in a wide range of applications. They are available in various sizes, configurations, and materials, allowing them to be tailored to specific needs. Spur gears can handle different torque and speed requirements, making them suitable for both low and high-speed applications.

- High-Speed Capability: Spur gears can achieve high rotational speeds due to their straightforward design and direct tooth engagement. They are capable of transmitting power efficiently at high speeds, making them suitable for applications that require rapid motion or high rotational velocities.

- Precise Positioning: Spur gears provide accurate positioning due to their precise tooth engagement. The straight teeth allow for precise control of rotational motion, making them suitable for applications that require precise positioning, such as robotics, machinery, and automation systems.

- Cost-Effectiveness: Spur gears are often cost-effective compared to other gear mechanisms. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings.

- Reliability: Spur gears are known for their reliability and durability. The direct tooth engagement provides excellent load distribution, minimizing stress concentration and wear. When properly lubricated and maintained, spur gears can operate reliably for extended periods, making them suitable for demanding industrial applications.

- Wide Availability: Spur gears are widely available in the market, with various sizes, materials, and configurations to choose from. This availability ensures easy sourcing and replacement of gears when needed. Additionally, spur gears have been used for many years and have a well-established design and manufacturing process, leading to a robust supply chain.

These benefits make spur gear mechanisms a popular choice in numerous industries, including automotive, machinery, robotics, aerospace, appliances, and more. Their simplicity, efficiency, compactness, versatility, and reliability contribute to their widespread use in a wide range of applications.

editor by Dream 2024-05-08

China Custom OEM Large Worm Gear Spur Gear Helical Ring Gear and Pinion Truck Gear spiral bevel gear

Product Description

1) According to the different strength and performance, we choose the steel with strong compression;

2) Using Germany professional software and our professional engineers to design products with more reasonable size and better performance; 3) We can customize our products according to the needs of our customers,Therefore, the optimal performance of the gear can be exerted under different working conditions;

4) Quality assurance in every step to ensure product quality is controllable.

Product Paramenters

| DRIVEN GEAR |

NUMBER OF TEETH |

12 |

|

MODULE |

4.5 | |

|

LENTH |

372 | |

|

OUTER DIAMETER |

ø60 |

|

|

DIRECTION OF SPIRAL |

R |

|

|

ACCURACY OF SPLINE |

M27*1.5-6g | |

|

NUMBER OF SPLINE |

13/18 |

|

DRIVEN GEAR |

NUMBER OF TEETH |

56 |

|

OUTER DIAMETER |

ø251 |

|

|

DIAMETER OF INNER HOLE |

ø149 |

|

|

ACCURACY OF SCREW |

10-M10*1.25-6H | |

|

CENTER DISTANCE OF SCREW HOLE |

ø177 |

|

|

DIRECTION OF SPIRAL |

L |

Company Profiles

Our company,HangZhou CHINAMFG Gear co.,Ltd , specialized in Hypoid and spiral bevel gear used in Automotive industry, was foundeded in 1996, with registered capital 136,8 square meter, with building area of 72,000 square meters. More than 500 employees work in our company.

We own more than 560 high-precise machining equipments, 10 Klingelnberg Oerlikon gear production lines, 36 Gleason gear production lines, 5 forging production lines 2 german Aichilin and 5 CHINAMFG CHINAMFG advanced automatic continuous heat treatment production lines. With the introducing the advanced Oerlikon C50 and P65 measuring center, we enhence our technology level and improve our product quality a lot. We offer better quality and good after-sale service with low price, which insure the good reputation. With the concept of “for the people, by technology, creativity, for the society, transfering friendship, honest”, we are trying to provice the world-top level product.

Our aim is: CHINAMFG Gear,world class, Drive the world.